Product Development Optimization

We understand that every product development involves costs, so we meticulously respond to your expectations.

We stand by your side to solve design, mold, mass production, and production line integration challenges for you.

Our core value lies in our strong design and process integration capabilities. Our professional technical R&D team understands your product requirements, part characteristics, steel material selection, and plastic material properties (such as PEI, POM, PPO, PA, PBT, etc.) to conduct professional analysis. We plan annual production capacity and process capacity, helping you overcome development and design challenges. We provide excellent mold design solutions, with consistent responsibility for each process, offering you the most optimized suggestions, risk assessments, and mold warranty services. We work with you to ensure the quality and stability of mass-produced parts, enhancing the success rate of product development and the quality of mass production.

Our R&D team has many years of experience in reverse engineering and mold disassembly integration. We develop inspection tools in-house to meet your mass production inspection needs, controlling the precision of subsequent processes in advance to ensure the quality of mass-produced parts. Our comprehensive technical improvement services have assisted numerous clients in advancing their R&D efforts, earning multiple patent certifications over the years.

精工股份有限公司的核心價值在於擁有強大的設計開發與工序整合能力,由我們專業的技術研發團隊了解您的產品需求、零件特性、鋼材選用、塑膠材料特性 (PEI、POM、PPO、PA、PBT…等) 進行專業分析、年產量與製程產能規劃,陪同您解決開發設計難題,協同提供良好的設計開模方案,一慣式的服務對每個工序負責,提供您最優化的建議、風險評估、模具保固服務,與您一同確保零件量產的品質與穩定性,提升產品開發的成功率與大量生產的品質。

我們的研發團隊在逆向工程與拆模技術整合有多年經驗,藉由對合您的量產檢驗需求,自廠加工開發檢治具,事先控管後工序精度,為您確保零件量產的品質。完善的技術改良服務,多年來協助眾多客戶研發精進,取得多項專利認證。

|

廠內使用塑膠材料 Resin Used in Dahorn |

| 泛用塑膠 Commodity Thermoplastic |

工程熱塑性塑膠 Engineering Thermoplastic |

高性能塑膠 Performance Thermoplastic |

彈性體與其他 Elastoplastics |

| ABS ( 聚苯乙烯 ) | PA ( Nylon/ 尼龍 全系列 ) | LCP | TPE |

| AS | PA6 ( Nylon6/ 尼龍6/ NY6 ) | PEEK | TPEE (HYTREL/ 海翠) |

| PE ( Polyethylene聚乙烯 ) |

PA12 (Nylon12/尼龍12/NY12) |

PEI | TPR ( SBS/SEBS ) |

| HDPE ( 高密度聚乙烯 ) |

PA66 (Nylon66/尼龍66/NY66) |

PES | TPU ( 優力膠 ) |

| LDPE ( 低密度聚乙烯 ) | PBT | PPS | PLA ( 聚乳酸 ) |

| PP ( Polypropylene聚丙烯 ) | PC ( 聚碳酸酯) | PSU | |

| PS (Polystyrene) | PC+ABS | ||

| PET | |||

| PMMA ( 壓克力 ) | |||

| POM (Celcon/ Delrin/ 塑膠鋼) | |||

| PPO |

| 廠內使用各種等級 Resin Grade |

| 光學級 Optical Grade |

防火阻燃級 Flame Retardant HB、V2、V1、V0、5VB、5VA |

耐衝擊 High impact strength |

耐化學級 Chemical Resistant |

| 醫療級 Medical Grade |

抗靜電 Anti-static |

耐熱級 Heat Resistant |

|

| 電鍍級 Plating Grade |

抗電磁干擾 EMI Electromagnetic Interference |

耐寒級 Cold Resistant |

|

| 食品級/ 水材級 Food/ Water contact Grade |

抗UV UV Resistant |

耐候性 Weather Resistant |

| 廠內使用各種添加物 Additive |

| 玻璃纖維 GF Glass Fiber |

碳纖維 CF Carbon Fiber |

玻璃珠 GB Glass Ball |

礦物纖維 MF Mineral Fiber |

產品與模具機構設計

科學輔助經驗分析診斷,為您控管風險與成本

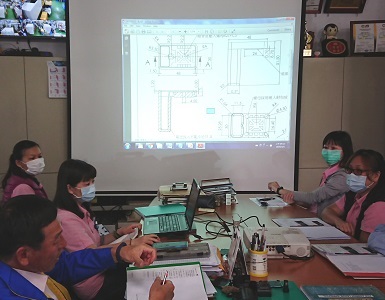

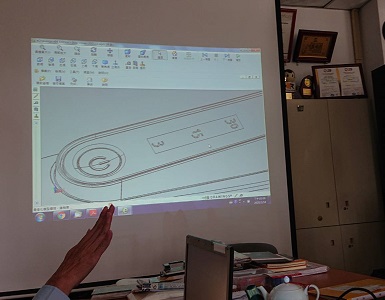

我們的研發團隊藉由電腦建置3D模型、確認2D公差、組配功能性,利用模流分析預測趨勢與誤差。密集的技術團隊會議,於拆模機構加工前,預測診斷產品與開模問題,為您事先把關並提供專業建言。藉由預先判讀與公差精細調整,保證模具加工精準性,為您縮短研發時程、降低設計錯誤與產品不良風險、有效節省成本。

廠內開發設計軟體Softwear List |

應用描述Description |

| AutoCAD |

2D 模具設計 2D Mold Design |

| Pro/Engineer |

3D CAD/CAM 拆模設計 3D CAD/CAM Mold Desing |

| SolidWorks |

3D CAD 拆模設計 3D CAD Mold Desing |

| NX CAD(Unigraphics UG) |

3D CAD 拆模設計 3D CAD Mold Desing |

| Moldex3D |

模流分析 Mold flow Analysis |