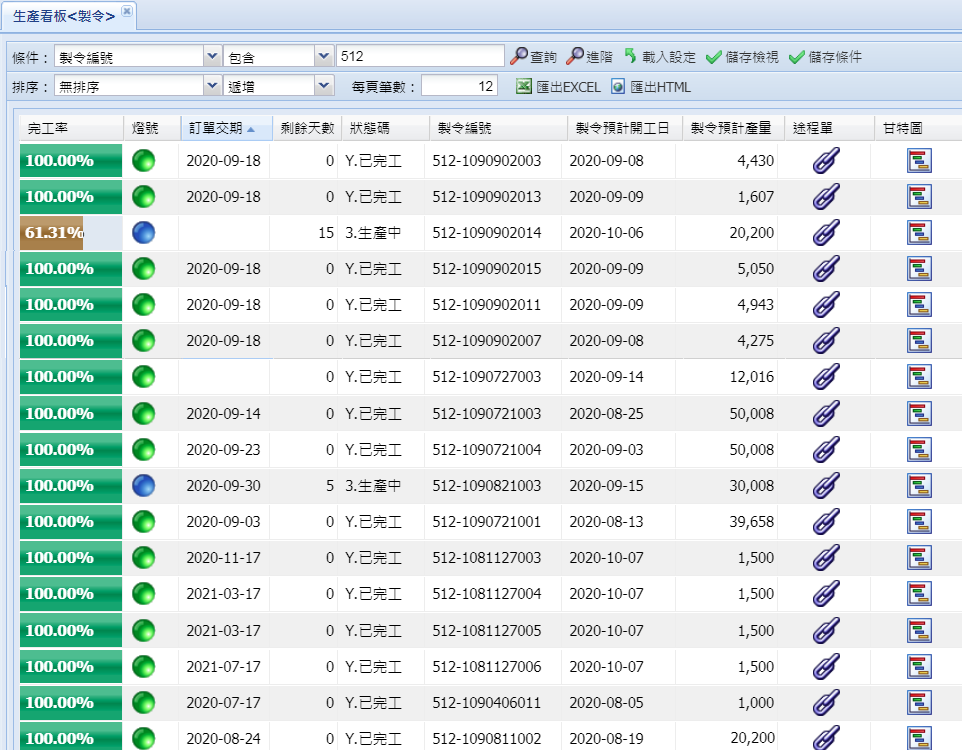

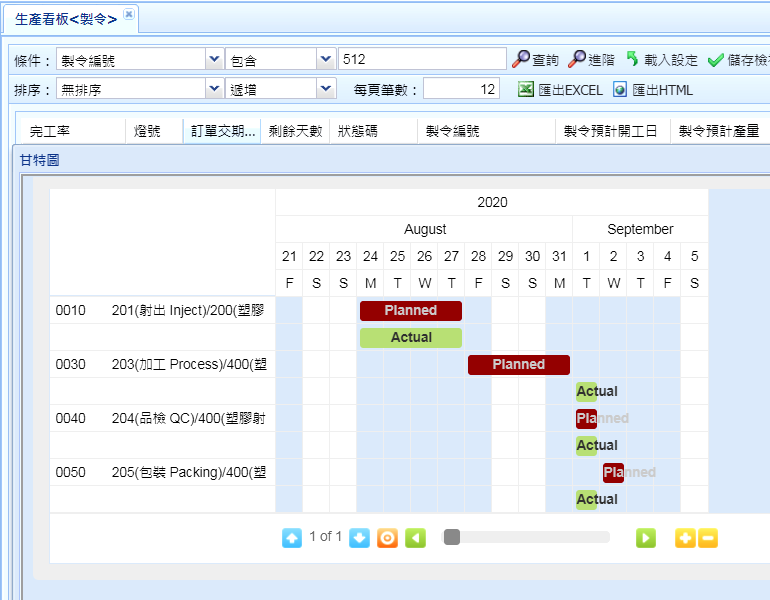

Mass Production and Schedule Control

預先為您規劃控管,做您的專業時程Planning and managing in advance, being your professional schedule steward.管家

製造業出貨控管,最怕供應鏈時程整合不良,時程過長導致斷線與交貨上市延遲。

我們的生產管理團隊,使用業界最嚴謹的ERP產能規劃、SFT多工序即時產能管理,為您量身訂做產能估算與時程排序規劃,配合國內外拉貨需求,預先做精準供應鏈管理。除單一製程量產規劃外,我們更專精於多工序製程、後加工、組立...等產程控管,保證出貨穩定順暢合時

In manufacturing shipment control, the biggest concern is poor integration of the supply chain schedule, leading to delays and missed delivery dates.

Our production management team uses the industry's most rigorous ERP capacity planning and SFT multi-process real-time capacity management to provide you with customized capacity estimation and schedule planning. We accurately manage the supply chain to meet domestic and international pull demand in advance. Besides single-process mass production planning, we also specialize in multi-process manufacturing, post-processing, assembly, and other process controls, ensuring stable and smooth shipment deliveries.

。

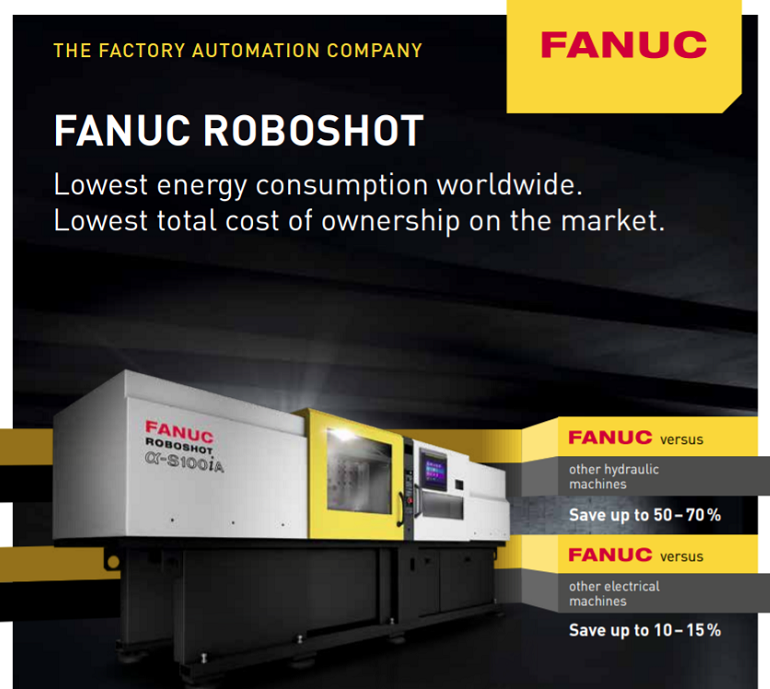

Injection Molding Testing and Precision Mass Production

Selecting the optimal molding equipment for you, eliminating unnecessary cost wastage

我們In our factory, we use leading Japanese brand injection equipment (FANUC) which includes high-quality all-electric precision servo and hydraulic crankshaft injection machines, internal and external core-pulling thread systems, dual alloy screw sets, Japanese (STAR) multi-axis automated robotic arms, mold monitoring equipment, vacuum dehumidifying dryers, automatic cutting systems, and automatic hole-punching systems. These are all optimized to provide a 24-hour mass production supply chain for your products.廠內採用日本領導品牌射出設備(FANUC),優良的全電精密伺服與油壓曲軸射出機、內外接抽芯絞牙系統、雙合金螺桿組、日本(STAR)多軸自動化機械手臂、金型監視設備、真空除濕乾燥機、自動切斷系統、自動分穴系統,為您的產品提供最優化的24小時量產供應鏈。

<Injection Molding Technology and Capabilities>

Production Capacity: 24 hours, 3 shifts, 21 precision injection machines.

Injection Machine Equipment: 15T~250T

Maximum Size of Plastic Products: 300mm x 300mm x 120mm

Minimum Size of Plastic Products: 1mm x 1mm x 1mm

Thinnest Plastic Product Thickness: 0.8mm x 0.8mm x 0.8mm

Precision for Plastic Products: Tolerance of ±0.01mm ~ ±0.02mm

| Tonnes | Brand | Type | Distance Between Column W×H (mm) |

Max Distance Between Mold Surface (mm) |

Mold Thickness (mm) |

Max |

Ejecting Stroke |

Max Injecting Volume (g) |

|

| 250T | Victor | Hydraulic | 610 | 610 | 1130 | 250~550 | 580 | 120 | 541g PS |

| 180T | Victor | Hydraulic | 510 | 510 | 970 | 200~500 | 470 | 100 | 315g PS |

| 130T | Victor、TOYO | Hydraulic、Electric | 460 | 460 | 850 | 150~450 | 400 | 80~100 | 103 cm3 |

| 100T | FANUC、Victor | Hydraulic、Electric | 410 | 410 | 750~790 | 150~450 | 350 | 80~100 | 50 cm3 |

| 50T | FANUC、TOYO | Electric | 310 | 310 | 590~600 | 150~350 | 250~270 | 70 | 24~43 cm3 |

| 30T | FANUC、TOYO | Electric | 260 | 260 | 530~560 | 120~330 | 230 | 60 | 11~13 cm3 |

From: https://www.fanuc.eu/uk/en/roboshot